2023, PRODUCT DESIGN, ENGINEERING

Optimizing a patient lift with Siemens NX

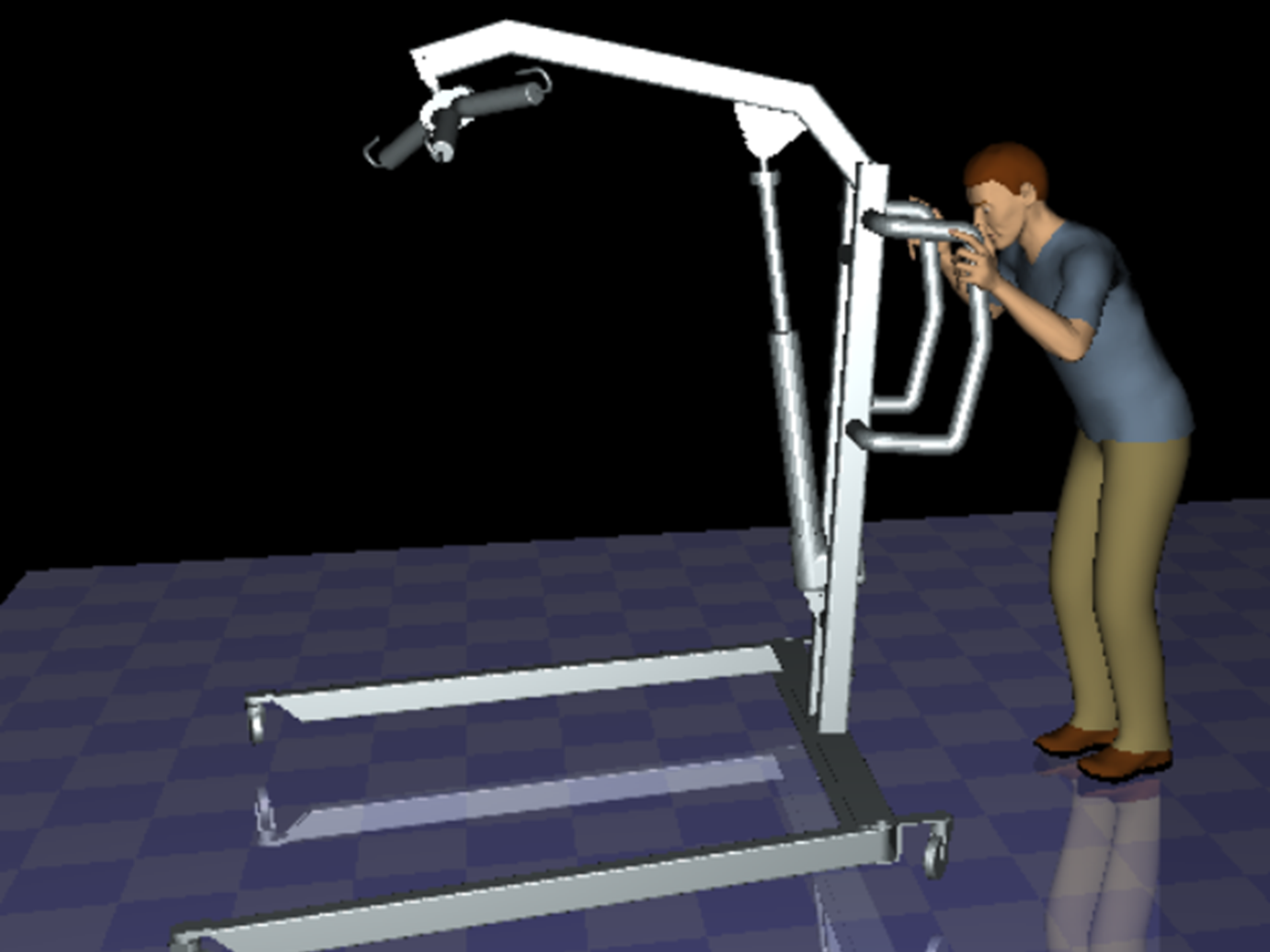

During this group project in the first year of my Master Industrial Design Engineering, I redesigned a patient lift with the use of Siemens NX. This assignment was done for the course “Advanced 3D modelling”, which taught us how to use parts of Siemens NX. During the project, we used 3D modelling and simulation tools, to build and analyse our optimization of the patient lift.

3D Modelling

An existing Max 350 passive patient lift was modelled in Siemens NX using the manual dimensions with a four-point yoke. It was assumed that the whole model is made out of Steel (AISI-Steel-1005) and the wall thickness is currently 1 cm. Since an objective is to minimize the mass of this model, two extra iterations were made with a wall thickness of 0.5 mm and 0.1 mm.

Forces and displacement

A displacement analysis was performed on several subassemblies. As a constraint, the back of the top arm was fixed. A force of 1500 N is distributed over the four hooks of the patient hanging system, as to represent a person hanging under the system. A solution was created with these settings, after which the displacement and stress experienced in the lift were analysed. The analysis was repeated with different wall thicknesses.

Topology optimization

A topology optimization was done to find the maximum displacement at the weight limits of the 10 mm, 5 mm and 1 mm top arm beam. This arm was selected for optimization because most of the load is placed onto this beam. The total weight of the different beam thicknesses was measured and used as mass constraints during a topology for stress optimization.

Ergonomics

The Jack and Jill program was used to make an ergonomics analysis. The human in the program is pushing and pulling the healthcare lift with and without a person in it. It is tested with different assemblies which are lighter than the original one to see if it is better for the human and if this makes a difference. The different assemblies with different weights have an impact on the force that works on the human.

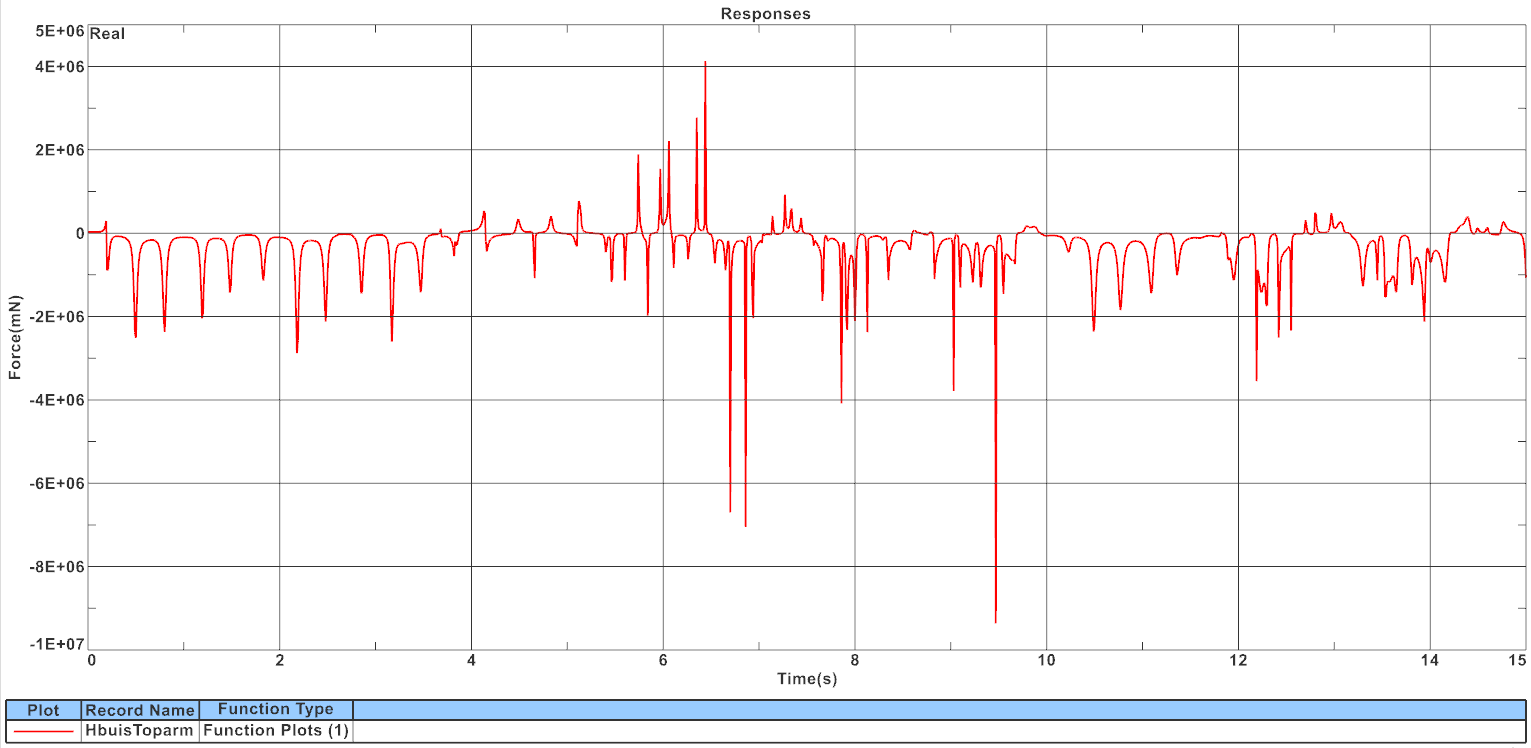

Motion analysis

A motion analysis was performed on the three different wall thicknesses of the model to determine if the thinner wall thicknesses negatively influence the amount of swing of the patient. To simulate the patient hanging in the lift, four strings and a ball of approximately 150 kg were attached to the hooks of the patient hanging system.

Personal contributions to this project

During this project, the different types of analyses were divided among the team members. Making the 3D model, doing a topology optimization, and conducting the motion analysis were my responsibilities. I used my experience in other CAD and simulation software, including SolidWorks and Altair, to complete the project. I learned about the different possibilities of Siemens NX and gained some practical experience in working with the software.

Personal contributions to this project

During this project, the different types of analyses were divided among the team members. Making the 3D model, doing a topology optimization, and conducting the motion analysis were my responsibilities. I used my experience in other CAD and simulation software, including SolidWorks and Altair, to complete the project. I learned about the different possibilities of Siemens NX and gained some practical experience in working with the software.