2024, PRODUCT DESIGN, ENGINEERING

Redesigning a bone cutter

This project was done for the course “Medical Certification & Human Factors”, which is part of the study Biomedical Engineering. The objective was to redesign a medical device to comply with the MDR, using official standards.

The Medical Device Regulation is a law that all medical devices have to comply with. Different rules are in place for different classes of medical devices. A bone cutter is a typical Class I device. It is a reusable surgical instrument, however, there are a few problems in its usability. A lot of force is required to operate the device, which makes it difficult for some surgeons to use a bone cutter. Therefore, a redesign was made that used a ratchet system to increase force amplification. Guidelines and rules of the MDR were used during the process of the redesign.

Existing bone cutter versus redesign

A complete risk analysis was done to find points of improvement for the redesign. Usability risks, biohazards and mechanical risks were among others investigated. Risks that were identified in the original bone cutter are the risks of infections, physical injuries, and inaccuracy. This is caused by a large number of parts, protruding parts, limited line of sight, and different types of nuts and bolts that make assembly difficult. In the redesign, this was solved. The ratchet mechanism was moved inside the bone cutter, which improved the line of sight and reduced the risk of patient injury. Handles were added that provide grip for the hands of the surgeon to reduce slips and mistakes. All different types of nuts and bolts were changed to a single type of shoulder bolts that are integrated into the parts. Finally, the number of different components was reduced by combining parts, taking producability into account.

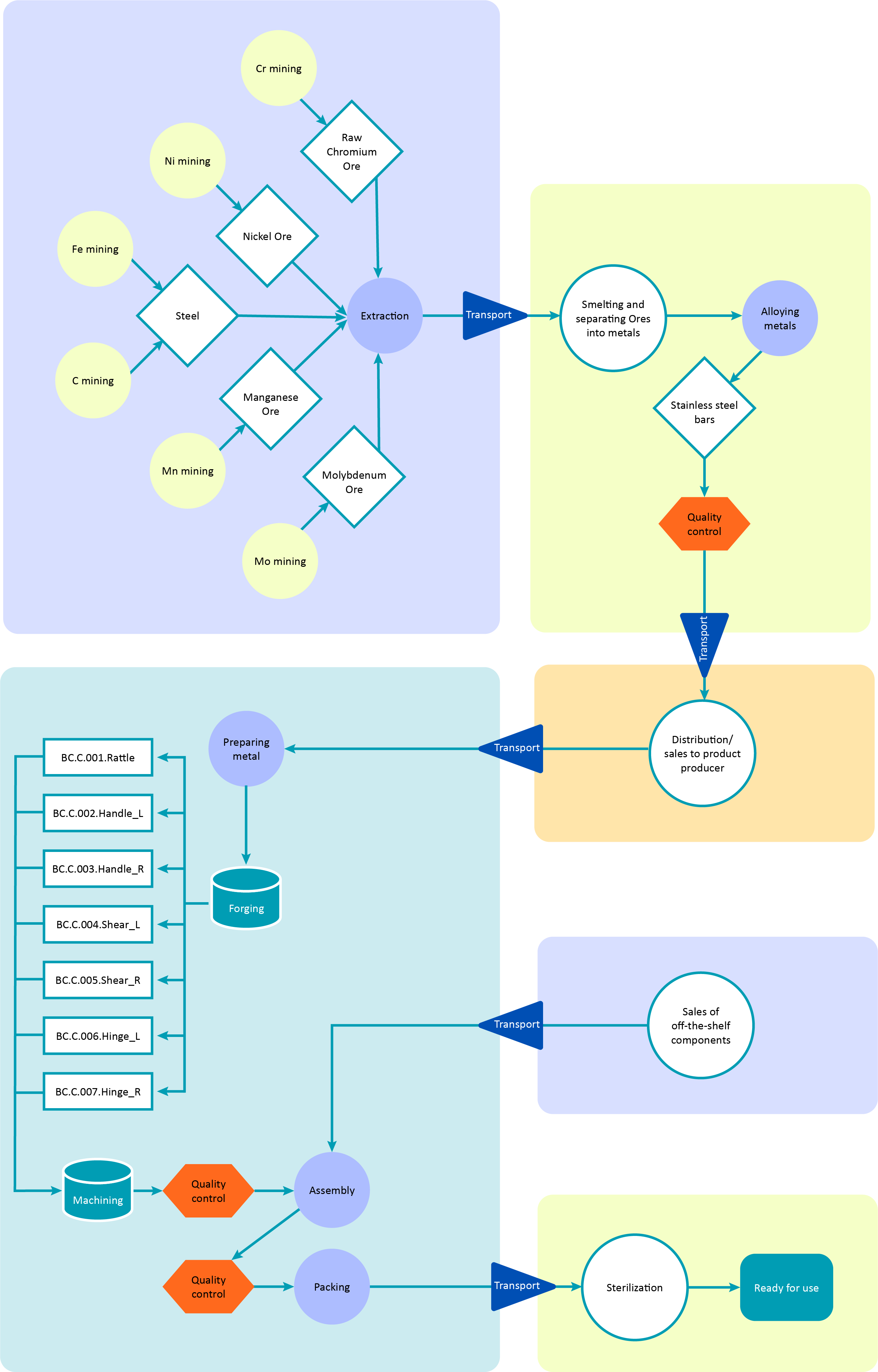

Manufacturing flowchart

Further research was done into opportunities based on the established framework. Two specific approaches within this framework were examined: learning emotional skills through games, and stress reduction through exercise instead of eating. The objective is to explore the potential benefits of these interventions in managing stress and anxiety and fostering emotional resilience.

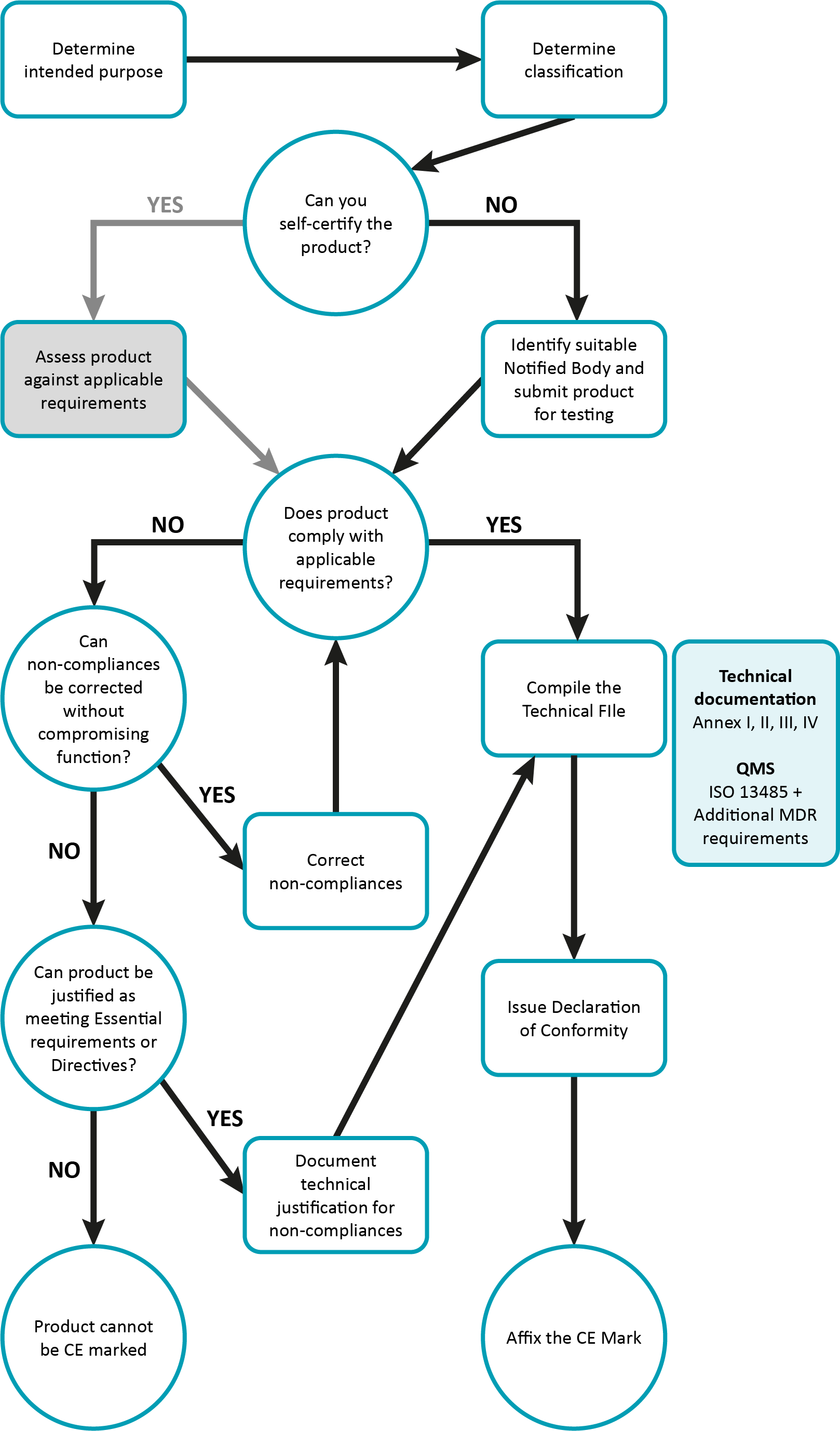

CE marking

Part of the assignment was also to follow the steps to get a CE mark. The bone cutter can be classified as a Class Ir medical device, since it is a reusable surgical device. This means that a notified body should be involved. During the project, we compiled a technical file and wrote a test plan.

Personal contributions to this project

This project was part of the course “Medical Certifications & Human Factors”. This course was part of the study programme Biomedical Engineering. During the project, I worked with students from different disciplines, which made me realise that the skills I have learned in Industrial Design Engineering can be applied in many different settings. I was responsible for changing the mechanism of the bone cutter, which was a fun challenge. I was able to test the redesign by making a prototype on my 3D printer. In the end, I became familiar with the MDR rules and gained experience in designing medical devices.

Personal contributions to this project

This project was part of the course “Medical Certifications & Human Factors”. This course was part of the study programme Biomedical Engineering. During the project, I worked with students from different disciplines, which made me realise that the skills I have learned in Industrial Design Engineering can be applied in many different settings. I was responsible for changing the mechanism of the bone cutter, which was a fun challenge. I was able to test the redesign by making a prototype on my 3D printer. In the end, I became familiar with the MDR rules and gained experience in designing medical devices.